Innovative Applications of Metal Fabrication in Modern Manufacturing

Table of Contents

- Automation and Robotics

- Additive Manufacturing

- Artificial Intelligence in Fabrication

- Smart Factories and IoT Integration

- Sustainability Initiatives

- Advanced Welding Technologies

- Conclusion

Metal fabrication stands at the forefront of contemporary manufacturing, adapting through visionary innovations that enhance precision, efficiency, and versatility. As industries demand quicker turnaround, higher quality, and more sustainable solutions, companies specializing in Charlotte metal fabrication are adopting cutting-edge technologies to stay ahead of the curve. From robotics to artificial intelligence, these advancements are fundamentally altering the way products are designed, fabricated, and delivered.

Emerging trends, such as automation, smart factory adoption, and additive manufacturing, are not only streamlining production but also minimizing waste and reducing costs. These changes enable manufacturers to respond swiftly to complex design challenges and shifting market requirements while maintaining a commitment to quality. This rapid evolution underscores the crucial role of innovation in maintaining a competitive edge in today’s marketplace.

Within this environment, businesses must prioritize continuous learning and adaptation. By integrating the latest fabrication technologies and sustainability initiatives, manufacturers are building resilient and future-ready operations. Modern manufacturing is now defined as much by its technological prowess as by its skilled workforce, with a growing recognition that both must work in harmony to unlock the full potential of metal fabrication.

Furthermore, specialized services like knife sharpening support broader fabrication processes, ensuring that tools remain precise and practical—an often-overlooked yet essential aspect of quality manufacturing. Supporting and refining every link in the manufacturing chain ultimately leads to greater reliability and longevity of the end product.

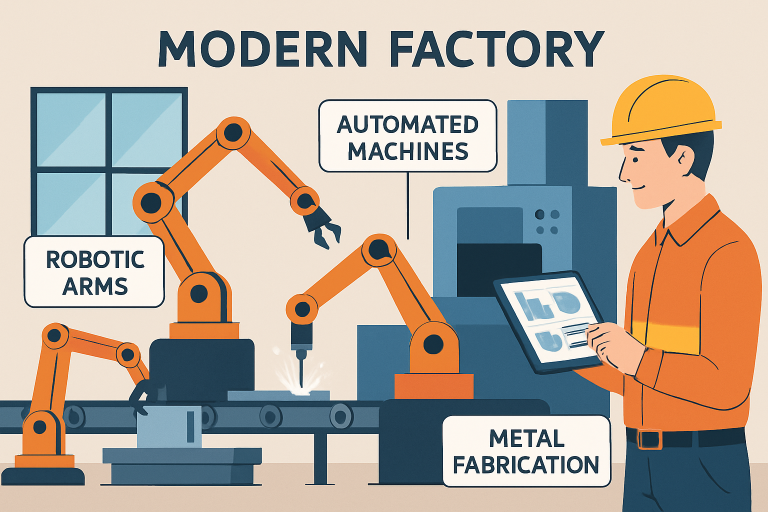

Automation and Robotics

The adoption of automation and robotics in the metal fabrication industry is a hallmark of its modern transformation. Robotic automation handles intricate and repetitive tasks, such as cutting, welding, and assembly, with exceptional precision and consistency. As collaborative robots—also known as cobots—work side by side with skilled technicians, they mitigate health hazards associated with mundane or hazardous tasks and drastically reduce error rates. Market data projects that the collaborative robot sector will reach $22.6 billion by 2032, reflecting manufacturers’ eagerness to adopt more innovative technologies for improved output and safer work environments.

Additive Manufacturing

Additive manufacturing, commonly known as 3D printing, marks a revolutionary shift in metal fabrication capabilities. Techniques such as selective laser melting (SLM) and electron beam melting (EBM) enable the production of components with previously unattainable intricacies, tailored to meet specific client needs and industry demands. The ability to create lightweight yet resilient structures with minimal material waste is gaining favor in the aerospace, automotive, and medical industries. Additive manufacturing’s agility and cost savings are helping reshape the very DNA of product development cycles, accommodating rapid prototyping and accelerating time-to-market.

Artificial Intelligence in Fabrication

Artificial intelligence (AI) is fundamentally changing how fabrication processes are managed and optimized. AI-powered analytics scrutinize massive volumes of data gleaned from every stage of production, revealing valuable insights for workflow enhancements and resource allocation. This not only enables predictive maintenance—identifying when a machine might fail before it happens—but also improves product quality through immediate defect detection. By streamlining decision-making and minimizing manual interventions, AI drives efficiency, reduces operational costs, and sustains a competitive edge. According to Forbes, AI’s impact on the manufacturing sector is set to intensify, with real-time monitoring quickly becoming a best practice for growth-oriented companies.

Smart Factories and IoT Integration

The proliferation of the Industrial Internet of Things (IIoT) has given rise to “smart factories”—digitally interconnected environments where every machine communicates and synchronizes with the rest of the system. Real-time monitoring not only boosts uptime but also empowers predictive maintenance and swift response to anomalies. Cloud-based solutions further enhance flexibility, enabling managers to remotely oversee production lines and streamline supply chains through precise, data-driven resource management. These innovations create a manufacturing network that is more collaborative, scalable, and responsive than ever before—enabling rapid adaptation to global market demands and helping maintain business continuity.

Sustainability Initiatives

Modern metal fabrication isn’t just concerned with productivity; sustainability is increasingly at the heart of new processes and strategies. Green manufacturing emphasizes recycling scrap materials, reducing water and energy consumption, and integrating machinery that lowers emissions. This holistic approach is in response to rising consumer demand for eco-friendly products, as well as increasingly stringent governmental regulations aimed at protecting the environment. Innovations such as solar-powered factories and circular production models are emerging, enabling manufacturers to reduce their carbon footprint while maintaining profitability. As the Environmental Protection Agency (EPA) highlights, sustainable manufacturing is becoming essential for future industry leadership.

Advanced Welding Technologies

Welding technology remains foundational to the strength and durability of fabricated components. Innovations such as laser beam welding (LBW) and friction stir welding (FSW) are integral to producing joints that are not only robust and precise but also less prone to contamination and defects. These advanced welding technologies are particularly vital in sectors such as aerospace and automotive, where performance and reliability are non-negotiable. As new alloys and materials emerge, advanced welding techniques will play a crucial role in expanding the boundaries of what is possible in both custom metalwork and mass production.

Conclusion

Metal fabrication is evolving at an unprecedented pace, fueled by breakthroughs in automation, AI, additive manufacturing, and sustainability. Adopting these technologies is now mandatory for manufacturers aspiring to remain relevant, efficient, and responsible. As innovation accelerates and integrates into every facet of production, the modern fabricator becomes not just a maker, but a forward-thinking partner in solving tomorrow’s engineering challenges.