How Valve Repair Enhances Pump and Motor Performance and Longevity

Table of Contents

- Introduction

- The Role of Valves in Pump and Motor Systems

- Common Valve Issues Affecting Performance

- Benefits of Regular Valve Repair and Maintenance

- Best Practices for Valve Repair and Maintenance

- Conclusion

Introduction

Pumps and motors are the backbone of modern industrial operations, with their applications spanning virtually every sector, from manufacturing plants and municipal water treatment facilities to energy generation and chemical plants. Their uninterrupted function is critical to the daily workflow and productivity of these industries. At the heart of these dynamic systems are valves, which perform the essential roles of regulating flow and maintaining pressure, ensuring precise control over processes and upholding system integrity even under challenging or varying operating conditions. Given these responsibilities, the health and reliability of valves are directly tied to the overall effectiveness and safety of pump and motor assemblies.

When valves degrade—through physical wear, chemical attack, or operational errors—they can drastically reduce system efficiency and even halt vital processes. Problems such as leaks, misalignments, or obstructed flows often manifest as unplanned shutdowns, costly emergency repairs, and suboptimal output. Timely and trustworthy valve repair and sales NYC are invaluable not only for restoring equipment to peak performance but also for proactively managing risk and ensuring smooth industrial operations across the board. In this way, proper valve maintenance isn’t just routine care—it’s a strategic investment that preserves the utility and value of critical infrastructure over the long term.

Overlooking valve maintenance can have a ripple effect, leading to diminished energy efficiency, increased operational expenses, and an elevated risk of breakdowns or hazardous events. Valve issues do not remain isolated; they can propagate stress throughout pumps and motors, accelerating general equipment fatigue and consumption of spare parts. Implementing comprehensive repair and preventive care routines enables you to intercept minor problems before they escalate, minimize unscheduled outages, and extend the working life of your major assets. Ultimately, focusing on valve wellness serves as a pillar for achieving sustainable high performance and safeguarding both people and equipment in any sophisticated operation.

The Role of Valves in Pump and Motor Systems

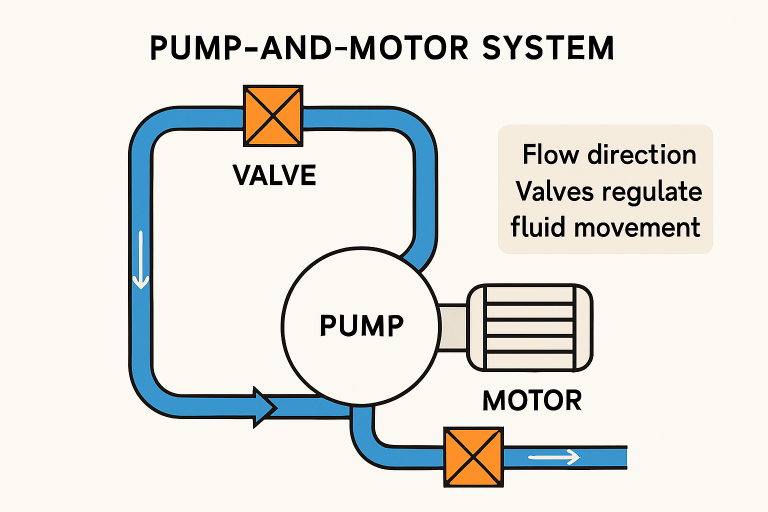

Valves occupy pivotal positions within pump and motor assemblies, modulating the quantity and pressure of fluids moving through pipelines and processing networks. By opening, closing, or throttling fluid passages as needed, valves can maintain a stable, efficient operating environment that meets production goals while meeting safety obligations. In a complex system, valves may switch flows between lines, isolate parts of the circuit for maintenance, or precisely control dosing in sensitive chemical processes. These responsibilities require every valve to function accurately and dependably, since deviations can ripple throughout the entire system.

A single malfunctioning valve—whether stuck, oscillating, or leaking—can have far-reaching consequences, from fluctuating line pressures and dangerous backflow to erratic vibrations and noises that signal more profound instability. These disturbances introduce stress on pumps by forcing them to operate outside their recommended operating ranges. Similarly, motors are forced to compensate, running at loads for which they may not be designed, which shortens their useful life and may require expensive overhauls.

Routine monitoring with flow meters and pressure gauges, along with regular inspections, is essential to detect abnormal valve behavior early. When issues are detected, swift intervention prevents extended stress on pumps and motors. Only when valves deliver airtight control can pumps and motors operate at intended efficiencies, resulting in peak lifespan and minimized energy loss. Proper valve health management thus underpins the reliability of the entire facility’s processes and protects capital investments.

Common Valve Issues Affecting Performance

- Leakage: Failed gaskets, worn seals, or warped seats are familiar sources of leaks in valve assemblies. These seemingly minor defects can lead to gradual but significant pressure losses, wasted product, and higher utility bills. Persistent leaks can also increase the load and wear on associated machinery.

- Corrosion: Valves exposed to corrosive chemicals, humidity, or extreme environments can degrade metal surfaces, leading to parts seizing, losing structural integrity, or crumbling. This corrosion reduces the suitability of affected valves for maintaining pressure ratings or resisting rupture.

- Blockages: Debris from upstream processes, mineral scale, or biological growth can accumulate in valve passages, obstructing movement or flow. Blocked valves fail to perform their intended function, leading to surging pressures or restricted flows that rapidly escalate into severe operating problems.

- Wear and Tear: The constant movement of valve internals — seats, discs, stems, and seals — gradually causes wear. Loss of material and precision contributes to inefficiency, increased clearances, and ultimately imperfect sealing that may lead to further mechanical problems.

Timely addressing of these common faults through expert repairs or replacements is vital to maintaining performance and preventing cascading failures, such as impeller wear, pump cavitation, overheated motors, or leaks throughout seal systems. Unresolved valve vulnerabilities often cause catastrophic breakdowns that can bring entire lines down—leading to potentially hazardous and expensive emergencies. The compounding risks of neglected valves underscore the need for proactive intervention and professional maintenance.

Benefits of Regular Valve Repair and Maintenance

- Enhanced Efficiency: Well-serviced valves enable precise control of liquids and gases, preventing energy loss from leaks or unnecessary pressure drops. When valves are routinely inspected and tuned, pumps and motors require less effort to maintain operational setpoints, resulting in improved throughput and optimal resource use.

- Extended Equipment Lifespan: Diligent valve maintenance intercepts wear and hidden stress before these can degrade vital equipment. Healthy valves protect pumps and motors from surges, overheating, or starvation, all of which are leading causes of premature failure, thus stretching the useful life of capital assets and reducing the frequency of major replacements.

- Reduced Downtime: Ensuring valves are always in peak condition translates directly into fewer unscheduled plant stoppages. Discovering, diagnosing, and correcting valve problems early means you can avoid costly production interruptions and focus resources on scheduled activities rather than unplanned crises.

- Cost Savings: Investing in regular maintenance and early repairs results in significant downstream savings. Avoiding energy waste, catastrophic breakdowns, premature pump or motor overhauls, and unscheduled outages can save substantial sums in operational budgets. Many organizations see rapid returns on their preventive care investments.

Best Practices for Valve Repair and Maintenance

- Regular Inspections: Establish a rigorous, scheduled inspection protocol for all valves, integrating periodic walkdowns, functional tests, and routine observations. Early identification of symptoms like sluggish response, surface corrosion, vibration, or minor leaks allows for small adjustments before persistent problems develop into emergencies.

- Use Quality Materials: Always specify and install valves made from robust, corrosion-resistant alloys or composite materials, especially for harsh process conditions. Superior material selection ensures fewer breakdowns and extends maintenance intervals, supporting long-term reliability.

- Implement Predictive Maintenance: Leverage tools such as vibration monitoring, temperature tracking, and IoT sensors that can detect developments in real time. These technologies provide advanced warning of impending issues, enabling maintenance to be efficiently planned and managed before failures impact production.

- Train Personnel: Provide extensive training for maintenance staff, including valve recognition, diagnostics, safe disassembly, and correct reassembly techniques. Knowledgeable teams are equipped to spot subtle signs of trouble and respond faster, thereby enhancing the quality and safety of repairs.

Conclusion

Optimal valve performance is essential for achieving ideal efficiency, reliability, and return on investment from industrial pump and motor systems. By prioritizing scheduled maintenance, rapid-response repairs, and smart upgrades, organizations ensure their most vital equipment assets perform at their best for as long as possible. These efforts not only mitigate the risk of disruptive failures and unplanned expenses but also drive significant gains in energy efficiency and system resilience. Ultimately, engaging experienced valve repair and maintenance specialists is the best assurance that your operation’s infrastructure will deliver enduring value, productivity, and peace of mind year after year.